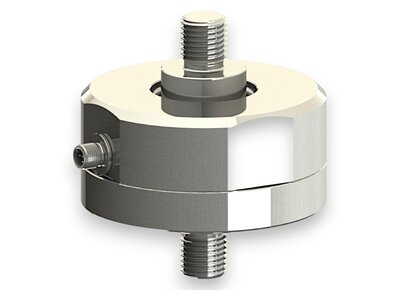

The factory calibration takes into account the requirements of DIN EN ISO / IEC 17025 and ISO 9000. The calibration certificate serves as proof of test equipment according to DIN ISO 9001: 2008.

Documented and evaluated are

- the general state of the sensor

- the span (reproducibility)

- the characteristics - and linearity error

at different load levels.

Note: For calibration with traction special adapters are needed for introducing force.

Without an adapter, it can lead to longer delivery times. The production of the adapter may cause additional costs.