Alignment specimens are important accessories when calibrating force sensors. With the alignment samples, the load introductions of the calibration device are aligned exactly. No moments or transverse forces then act on the test specimen. This is important because incorrect alignment would affect technical data such as linearity, reversal margin, etc.

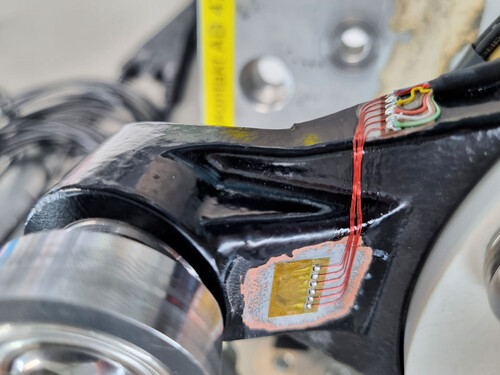

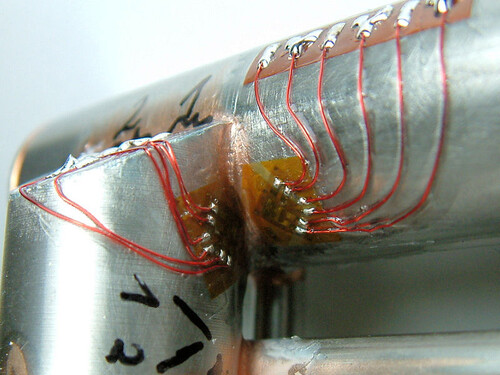

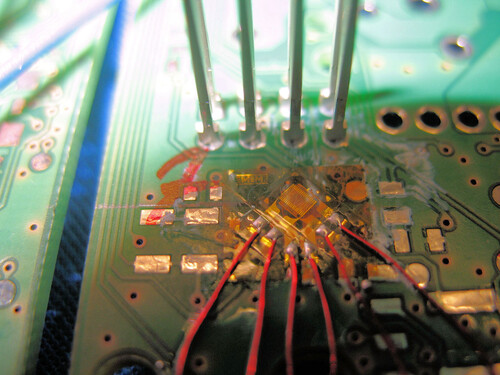

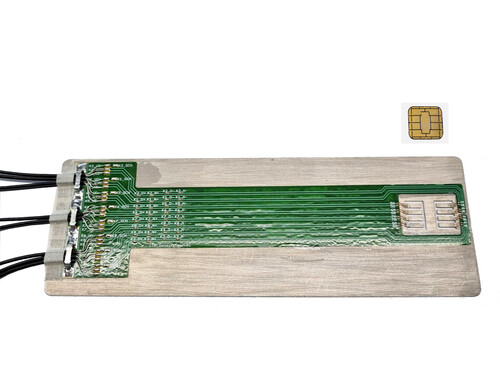

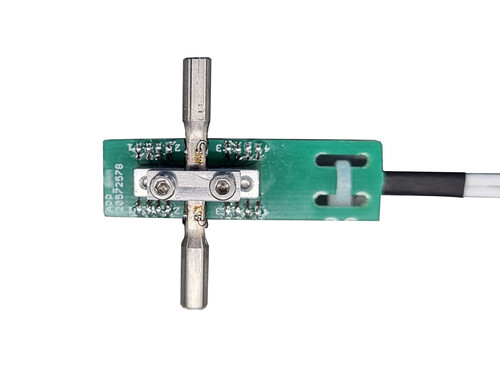

Alignment specimens are manufactured in various dimensions, with 8 to 12 independent channels.

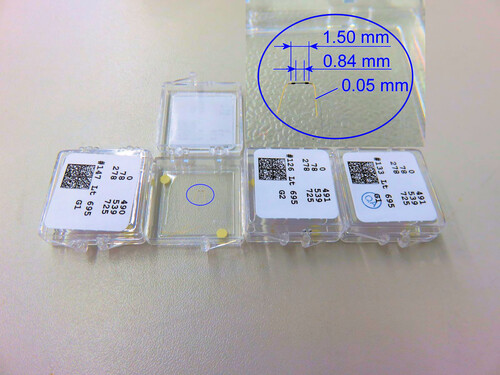

Strain gauge dimensions N2A-06-S5272H-120: 2.1 mm x 1.2 mm.

The two 12-core, shielded connection cables each have a diameter of 1.8 mm.