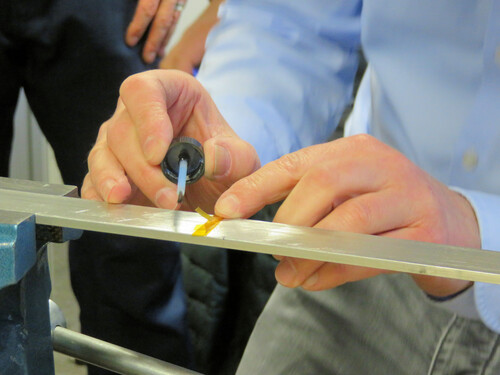

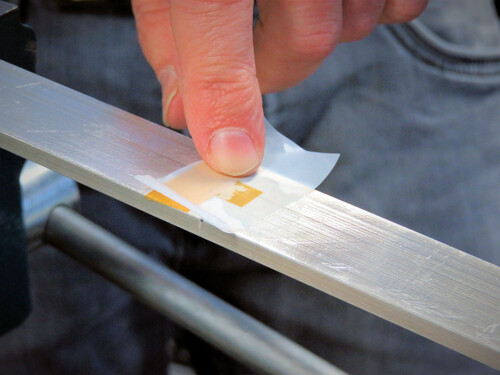

Strain Gauge (SG) Training

Need help installing strain gauges? We would be happy to support you with your measuring task and provide you with all the necessary basics on the subject of strain gauges.

The training courses can be designed individually according to your wishes. Your questions and components will be taken into account in the training.

We also offer the production of samples and series parts based on strain gauge technology. We would be happy to support you in the development of the products.