Evaluation of crack measuring strips

The spread of a crack can be detected electrically using a crack measuring strip.

The crack measuring strip “1-RDS22” from HBM consists of individual conductor tracks connected in parallel. It is glued over the end of the crack so that more tracks are gradually separated as the crack progresses.

The resistance of the crack gauge increases gradually as the crack propagates.

Circuit techniques for the evaluation of crack measuring strips

To measure the electrical resistance of a crack gauge, the following are suitable:

-

Resistance measuring bridges,

-

voltage dividers,

-

strain gauge measuring amplifiers.

Anyone who deals with stress analysis usually has a strain gauge measuring amplifier to hand. Therefore, there is a desire to connect a crack measuring strip to the measuring amplifier, although the use of a voltage divider or a resistance measuring bridge would be a less complex solution in terms of measurement technology.

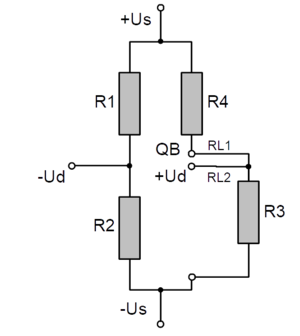

Figure 1

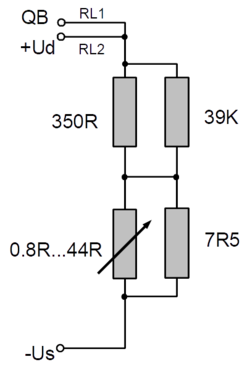

Figure 1 Figure 2

Figure 2