Production at ME-Measuring Systems

Sensors with strain gauges consist of a spring body that is equipped with strain gauges. To protect the strain gauges, protective covers or housings are required.

The quality of the sensor is determined by

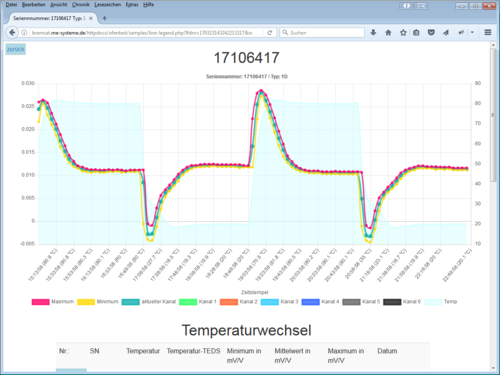

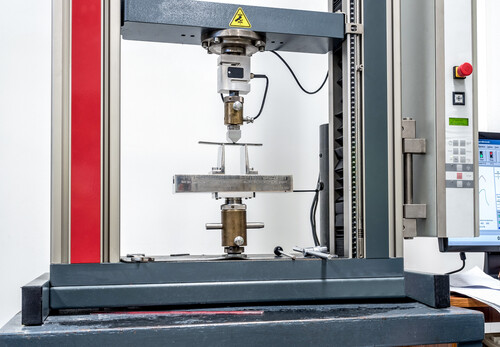

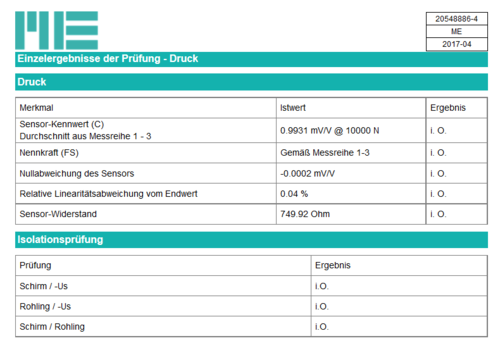

We monitor these properties through strict quality testing in incoming goods, through audits at suppliers, by measuring sensor properties such as temperature response, zero signal return error after thermal and mechanical stress, linearity, creep errors...

The slightest deviations in the process parameters, such as temperature, temperature gradient, roughness, purity, soldering temperature, thickness of the adhesive layer, etc., can affect the function of the sensor.

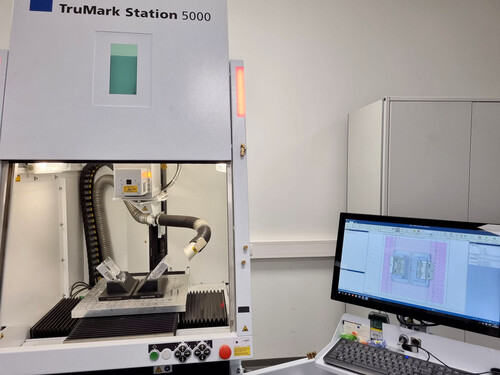

The safety of the processes is guaranteed by using the most modern production systems and measurement technology.

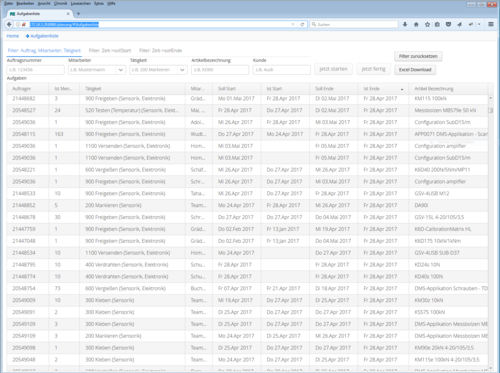

All production steps are monitored. Sensor properties are logged in databases.