CAN bus basics

General introduction

Interfaces are used to transfer information between the individual components of a system.

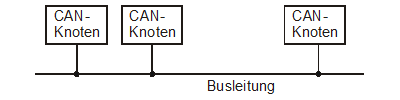

In a bus system, all components are connected to a common data line via short spur lines.

This minimizes the amount of cabling required and additional components can easily be connected.

However, the data flow must be controlled via an access procedure (protocol) if all components use a common bus line. If possible, components

components from different manufacturers should work together.

The Controller Area Network (CAN) connects several equally authorized components (nodes) via a 2-wire bus plus an additional ground line. The CAN protocol was developed by Bosch in 1983 for use in motor vehicles and was first presented to the public in 1986.

Figure 1: Controller Area Network (CAN)

Due to its high interference immunity, low costs and real-time capability, CAN is not only used in the automotive industry, but also in many other sectors (e.g. in commercial vehicles, mobile machinery, railroads, medical technology, industrial automation, elevators and as a machine bus system).

The organization “CAN in Automation” (CiA) is dedicated to the further development of the CAN protocol and the specification of the CANopen application protocol as well as the CANopen profiles.