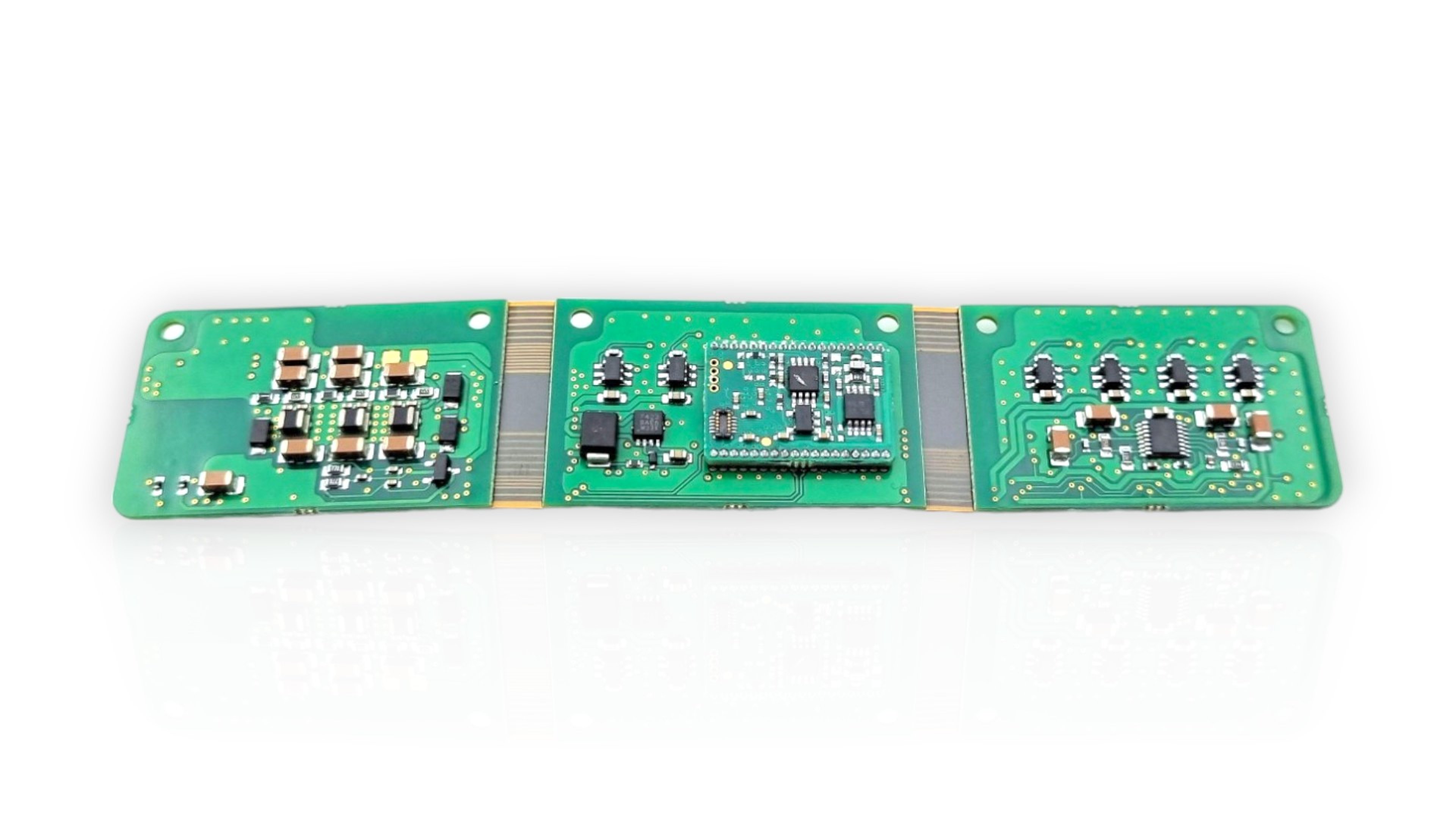

Measuring amplifier printed circuit boards

ME-Meßsysteme is a developer and manufacturer of measuring amplifiers and sensors. In the development of measurement amplifiers for sensors in strain gauge technology, such as. e.g. force sensors, torque sensors, strain transducers, etc., very high resolution requirements are placed: The (differential) output signal of the Wheatstone measuring bridge is a maximum of a few millivolts. This output signal should be resolved into, for example, 10,000 or 100,000 display steps, corresponding to 10 nanovolts to 100 nanovolts. Therefore, the highest demands are placed on the electronic components and the implementation of the electronic circuit.

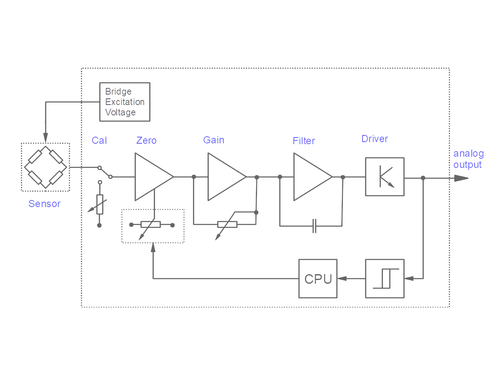

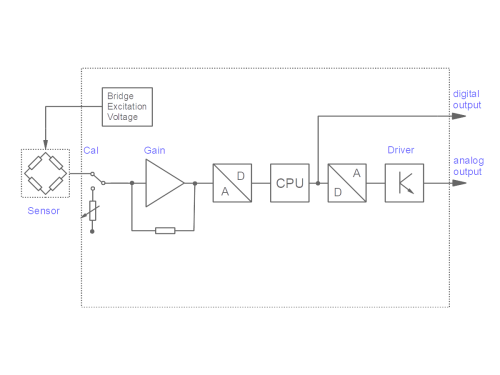

The low signal amplitudes result in further requirements for the offset stability of the electronic circuit in the event of temperature changes, for the lowest possible power consumption, and for the suppression of electrical interference.

The signals from force sensors and torque sensors are also used to control electric drives, which in turn places high demands on electrical interference immunity and bandwidth.

Many requirements, such as the requirement for high bandwidth and high resolution with the lowest signal amplitudes and often the smallest dimensions, can often only be implemented with great knowledge and extensive experience in the field of analog circuit technology.

ME-Meßsysteme GmbH specializes in “strain gauge technology” and has 30 years of experience in the development and production of sensors and electronics.