Measuring the resolution

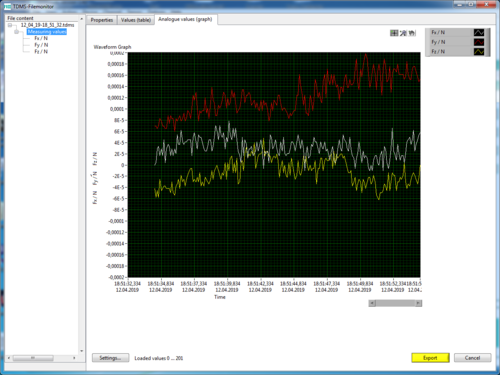

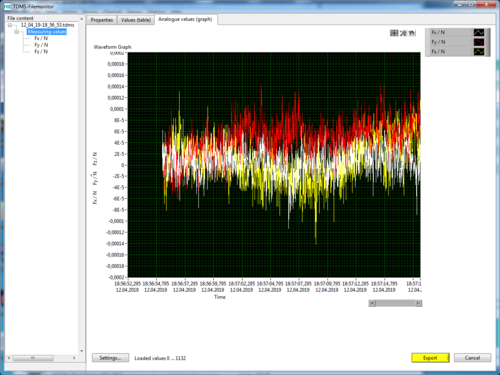

A "meaningful distinction" between two measured values is given, for example, when a person sees a clearly perceptible difference in the graphic display of the measured values. This means that the difference is visible over a sufficiently perceptible period of time and over a sufficiently perceptible amplitude.

Resolution = 1x noise amplitude (according to peak value definition)

ME measuring systems define the resolution as the difference between the maximum value and the minimum value of the last 10 seconds or alternatively the last 100 measured values.

This is a strict definition of resolution. Alternatively, you could use the RMS value of the last 3 seconds, or the last 30 measured values.

Transferred to a graphics screen, one could say: For the resolution, 1x line width must be a visible, clearly perceptible difference.

Parts = Measuring range / Resolution

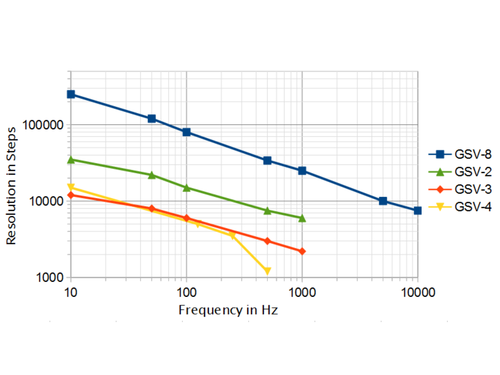

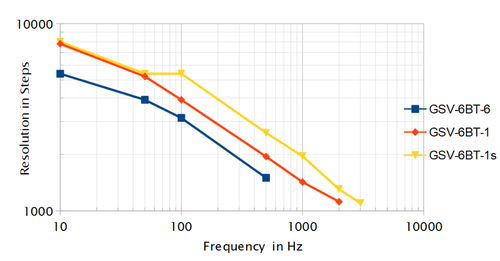

Since the absolute resolution is usually very small compared to the measuring range (e.g. 1/10,000 to 1/100,000 of the measuring range), and since it depends on the measuring range of the sensor, we at ME-Meßsysteme create a relative numerical value for the resolution: We relate the resolution to the measuring range and create the reciprocal of this (for better "readability").

Since the resolution is essentially determined by the measuring amplifier used, the resolution is related to the standard measuring range 2.0 mV/V or 3.5 mV/V of the measuring amplifier.

The resolution is therefore described by a numerical value. This numerical value describes how often the measuring range can be divided into line widths. The higher the number of parts, the better ("higher") the resolution.

The GSVmulti software allows the resolution to be displayed using different definitions: resolution as a numerical value in "parts", resolution as a dimensioned, absolute value "peak values max minus min", resolution as noise amplitude in decibels, etc.