Multi-component sensor assembly

The multi-component sensor consists of a hexapod rod structure arranged between two plates without additional joints. The sensor is (usually) made of a single piece of high-strength aluminum (3.1354) or high-strength, ferritic stainless steel (1.4542).

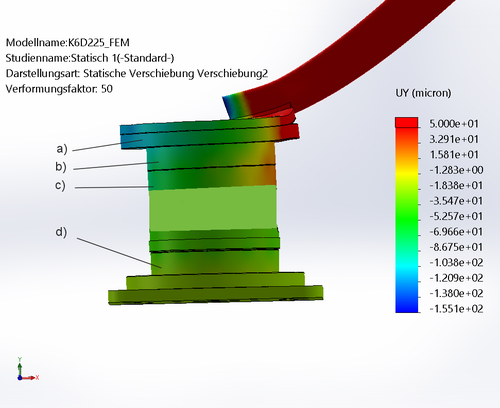

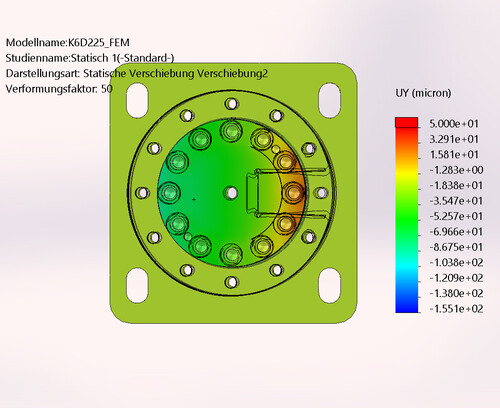

For the sensor to function properly, it is crucial that the front surfaces are not locally deformed.

A local deformation is caused, for example, if a point-like force Fz is applied in the center of the sensor.

The force is introduced across the circular ring between the inner centering collar and the outer diameter. The force is introduced on the trapezoidal circular ring segments. The recesses between the segments are not loaded.

In addition to the force introduction on the circular ring, the flatness and rigidity of the connection flange are important parameters. The material should be high-strength aluminum or tool steel 24CrMo4 or C60 tempered or high-strength stainless steel 1.4542. Plastic flanges from the 3D printer are unsuitable!

A screw that is not tightened can cause measurement errors of the order of 10% or more.

The tolerance for the flatness of the flanges is 0.02mm.

Table 1 provides guidelines for the thickness of the connection flanges and the recommended tightening torque. If the recommended tightening torque exceeds the nominal torque of the sensor, no torque should be passed through the sensor. Instead, the flange should be held directly against the sensor.

The screws should have a strength of at least 8.8. From 100Nm, screws 10.9 are recommended.