Selecting the Sensor

Another selection criterion for force-torque sensors is the diameter of the sensor: The diameter should be as large as possible.

Therefore, if you have to choose between the K6D27 and K6D40, the sensor model with the larger dimensions should be selected.

This rule can be applied accordingly to all other models K6D80, 110, 130, 150, 175, 225, and 300.

The measuring ranges of the 6D sensor for the torques are essentially determined by the diameter of the 6D sensor. By selecting a larger diameter, the crosstalk of torques on the force signal display can usually be reduced.

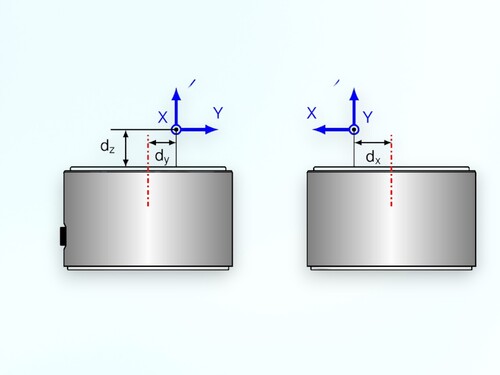

Consideration of the installation situation

The highest accuracy with a 6D sensor is achieved when forces are applied in the area of the sensor's face up to a distance of approximately 1x the diameter of the face.

As the distance of the force application from the face increases, the signal pattern becomes less defined, because a superposition of forces and moments is always introduced into the 6D sensor.

The sensor's mounting is subject to particularly stringent requirements: Local deformations of the force application flanges inevitably lead to measurement errors. The thickness of the counterflanges must be selected to avoid local deformations as much as possible. Recommendations for the minimum thickness of the flange plates are provided on the k6d-montage page. If even just one of the usually six fastening screws is not tightened or even not used, a measurement error will occur. Local deformations of the flange plates can occur, particularly when moments are introduced. Care must be taken to ensure that the flanges are as symmetrical as possible.

If this is not possible, calibration under the specific installation situation may be necessary.