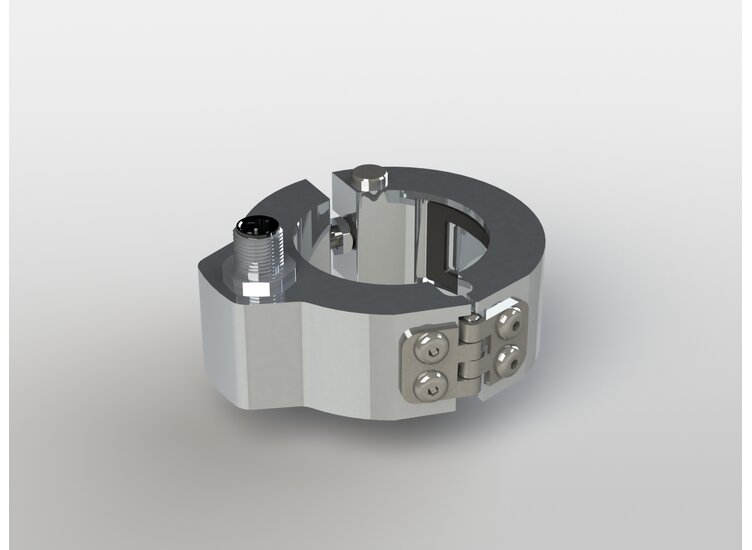

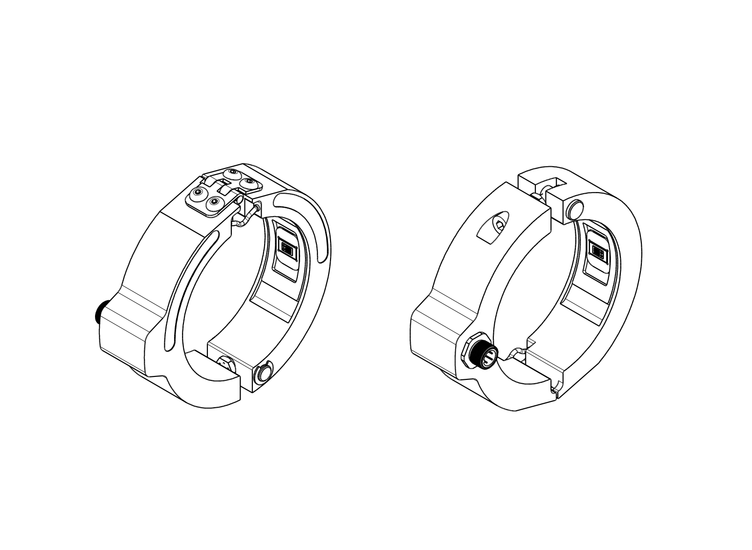

The two half-shells of the strain sensor DAdX are mounted on pillars to measure the compressive force of e.g. punches or the pretensioning force of tools. This strain sensor is suitable, like the DA40 and DA54, for both static and dynamic force monitoring.

As the strain sensor can be installed afterwards, it is a universal, retrofit sensor for monitoring force and load. The strain sensor is durable and resistant to oil and moisture.

This strain sensor with aluminum half-shells achieves the same performance as the direct application of strain gages. This includes high resolution and low drift. Every half-shell contains a completely wired strain gage full bridge, which is pressed and glued on the corresponding component by a special pressing mechanism, when the strain sensor is being screwed on. The housing serves as a mounting frame for the strain gage application. Possible bending forces in the column are compensated by parallel connection of the two strain gage full bridges.

Individual versions of the half-shells, e.g. with strain gage half-bridges in 90°-arrangement or with strain gage half-bridges for the torque measurement are possible.

Before screwing on the strain sensor, the surface of the component must be ground and cleaned in the zone of the strain gage. The strain gage is durably protected against moisture by a special, oil-resistant seal.

The zero balancing of the strain gage is carried out after the installation of the strain sensor by the strain gage measuring amplifier GSV-2 or GSV-1. Strains from 0.1μm/m onwards can be displayed. This corresponds to a mechanical stress of about 0.02N/mm2 on a component surface of steel. With the combination of strain sensor and measuring amplifier GSV-2, switching thresholds from about 1μm/m onwards (corresponding to 0.2N/mm2) can be monitored, if a zero balancing is carried out periodically.