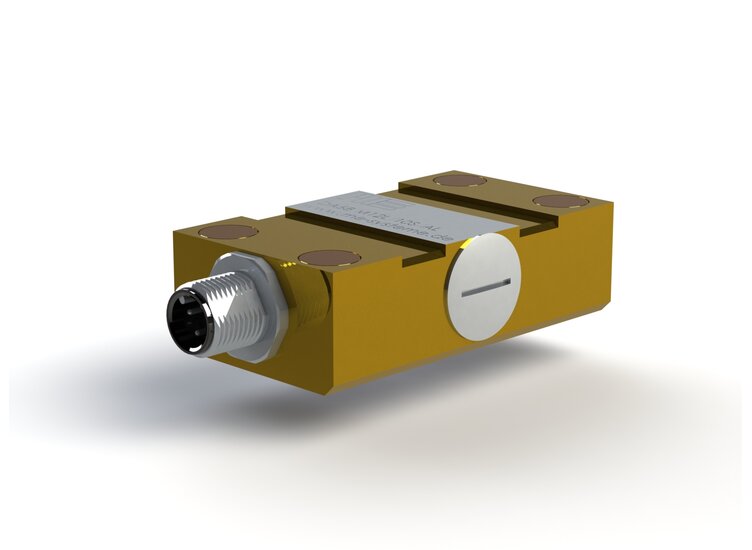

The strain sensor DA68 is suitable for high-resolution detection of forces and deformation of structural works such as bridges, silo legs, offshore wind farms, railway lines, etc.

With these models in an anodised aluminium or stainless steel housing, the same performance features are achieved as when applying strain gauges (DMS) directly. These features include a high resolution, very low drift effects and the options for both static and

dynamic measurement.

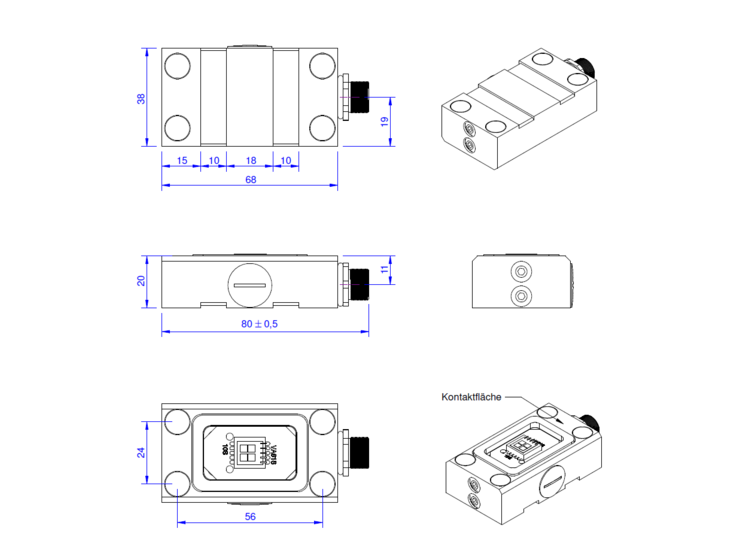

The strain sensor includes a completely wired DMS that is pressed onto the component by a specially formed pressing mechanism when mounting the strain sensor. An

integrated seal provides an initial layer of protection against dust and damp. The strain sensor has two filler pipes for casting with cable resin after installation. Depending on the planned duration of use, additional measures to protect against damp, such as waterproofing the joints with silicone, encapsulation with additional surrounding hoods, etc. are applied after installation. Unlike strain sensors DA40 and DA54, the contact with the surface is generated by integrated high-performance magnets. Time-consuming drilling of threads is not required as a result. The housing of the strain sensor and the strain gage are glued with the surface in a common process. The strain sensor can also be used for stress analysis in offshore applications. The strain gauges are also evaluated as active quarter bridges and are supplemented with passive precision resistors within the strain sensor.

The strain sensors of the series DA68e contain an integrated measurement amplifier of type GSV-15L.