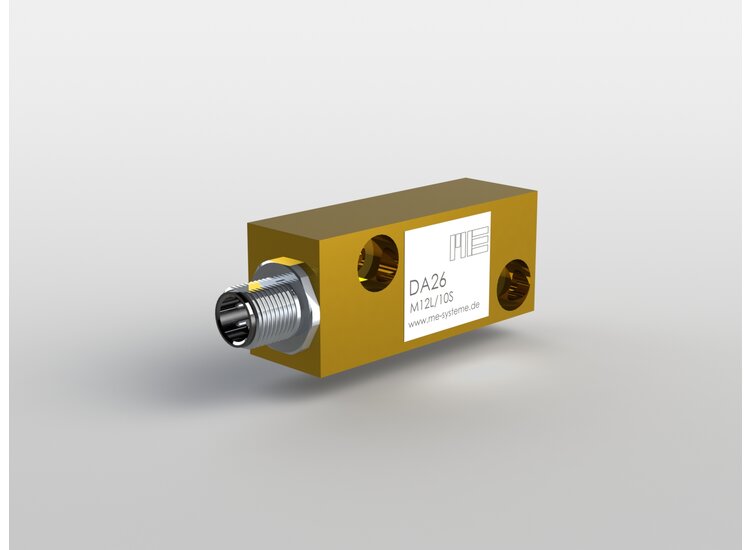

The DA26 extension sensor is suitable for high-resolution detection of forces and deformations on massive components e.g. presses, hoists, containers, steel girders, bridges, connecting rods or frames of manufacturing machinery.

Subsequent installation makes these extensions sensors universal, retrofit sensors for force and load monitoring. These extension sensors are durable and resistant against oil and moisture.

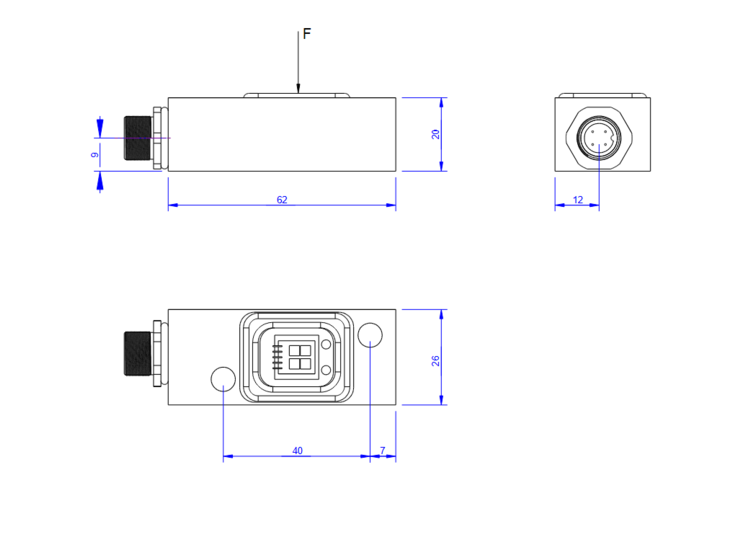

The most efficient assembly is across the load direction. No force can be transferred thanks to the housing. However, assembly along the direction of compression is possible for strains of up to 100µm/m without limiting accuracy. The DA26 sensor is also available without countersink for assembly with superimposed threaded bolts.

With these extension sensors in a robust and easy-assemble aluminium housing, the same performance features are achieved as when applying strain gauges (DMS) directly. These features include a high resolution, very low drift effects and the options for both static and dynamic measurement.

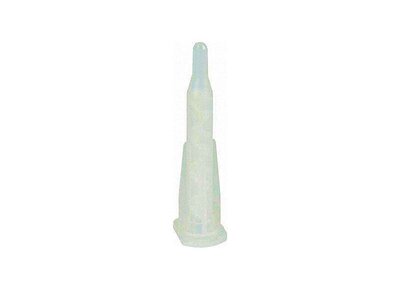

The extension sensor includes a completely wired DMS that is pressed onto the component to be bonded by a specially formed pressing mechanism when screwing on the extension sensor. Thus the housing serves as a mounting frame for the DMS application.

The surface of the component must be sanded down and cleaned in the strain gauge area before screwing on the extension sensor. The DMS is protected permanently against moisture through a special oil-resistant seal.

The zero adjustment of the strain gauge is performed after assembling the extension sensor of the GSV-2 DMS measuring amplifier. Strains from 0,1µm/m can be displayed.

This corresponds to a mechanical tension of approx. 0,02N/mm2 on the surface of a steel component. With the combination of extension sensor and GSV-2 measuring amplifier, switching thresholds from approx. 1µm/m (corresponds to 0,2N/mm2)can be monitored if a zero adjustment is performed periodically.

For applications in weighing technology, an extension range of at least 30µm/m (6 N/mm2) is recommended to achieve the lowest possible drift effects.